Radial fans

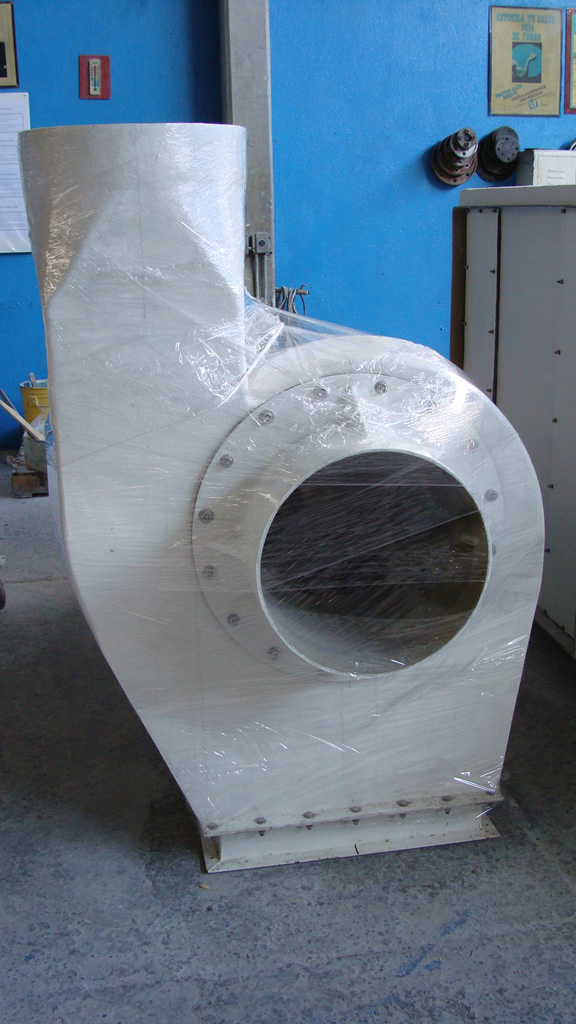

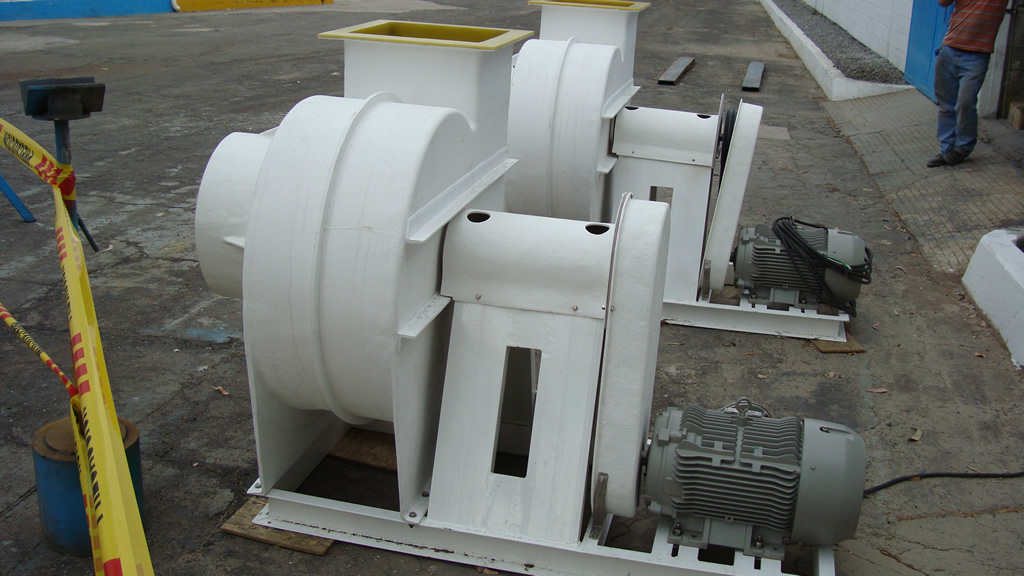

1. Description: Radial Centrifugal Fans are mechanical equipment designed to take charge of moving a volume of fresh air with or without contaminants in a certain amount of time from a point of extraction; in some applications the gas stream passes through cleaning devices like a scrubber and in others it is released directly into the atmosphere. Operation of this equipment is based on the delivery of mechanical power to the air by way of a rotor that rotates at high speed.

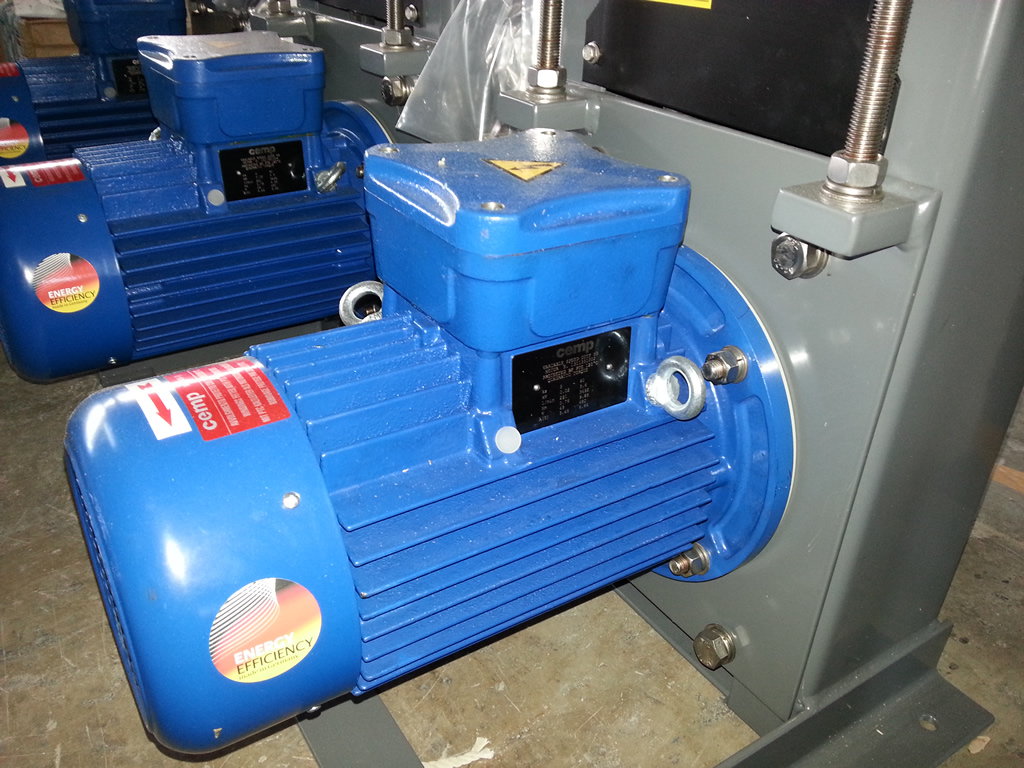

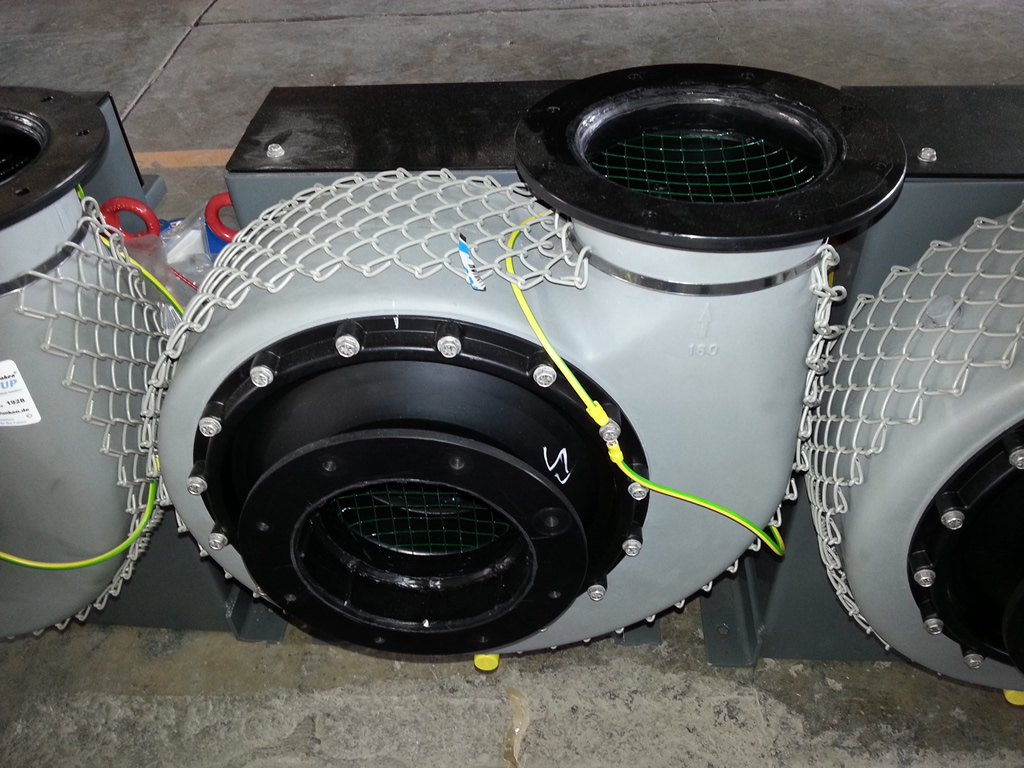

Lapsolite from the moment it was acquired by the Hürner GmbH company, being a leader in the manufacture of plastic fans (www.huerner-funken.de), has allowed us to have a high degree of specialization, to offer plastic centrifugal fans as a better alternative at the level of systems for the injection and extraction of gases with materials more suited to the needs of our customers with the best price, quality and also, if necessary, compliance of materials and requirements according to ATEX regulations. Thanks to our experience on many projects we can offer the best solution according to the needs of the customer, with flows from 500 m3/h to 150,000 m3/h.

2. Ranges of design: The selection of a model of our radial fans depends on the required air flow, either for extraction or injection and total differential pressure required by the system.

LAPSOLITE has 4 series of fans with the following general characteristics:

|

SERIES |

16 |

13 |

130 |

48 |

|

RANGE OF FLOW [m3/h] |

100–9,999 |

2,000 –60,000 |

5,000 –100,000 |

100–6,000 |

|

ΔP TOTAL [Pa] |

100–1,400 |

180–1000 |

1000 –3000 |

1000 –6,000 |

For more information please refer to our catalog of radial centrifugal fans.

3. Applications: The use of fans has a wide and varied range since they are suitable for almost all types of industrial applications, as well as for residential use, hospitals, shopping centers, as well as other sectors.

4. Benefits:

a. The main beneficiary is the worker, independent of the function that he or she performs, will have an environment free of contaminants that guarantees good occupational health, efficient performance and a comfortable stay during his or her workday.

b. Centrifugal fans removes heat, humidity, polluting vapors and odors accumulated within a production or work area.

c. They reduce thermal loads generated by production processes.

d. Centrifugal fans raise the thermal control indexes: balance internal and external (in the shade) temperatures for a more comfortable atmosphere.

e. Centrifugal fans replace oxygen levels providing a healthier environment.

f. Centrifugal fans minimize the need for expensive networks of pipelines in new construction, for both heating systems and air conditioning.

g. Centrifugal fans can be manufactured with different materials that possess high physical and chemical resistance properties.

ENGLISH

ENGLISH